AEROSPACE

Your partner for function-critical parts that are crucial for the operation of your product

PARTS FOR THE AEROSPACE INDUSTRY

Alpes Usinage’s competitive and safe manufacturing processes, that even include traceability of the cutting tools, have been developed over 20 years with leading French aerospace companies.

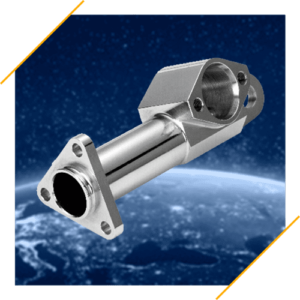

Example of a part for the aerospace industry

Magnetic filter cap – EN 9100-certified

We have developed a drain plug with integrated magnets. It is used for oil filtration in engines, e.g. for aerospace in order to increase the performance, reliability and longevity of the engines.

High precision machining to ensure perfect operation of each of the 10 components (magnets, pins, bush, valve, sleeve, springs, tube, nozzle, cylinder).

The advanced and competitive surface treatment technology produces optimal flow properties and guarantees the separation of ferrous elements. The unique Tech critique™ process defined by Alpes Usinage’s engineering department is adapted to small series; it ensures quality control and integrates total traceability including on the assembly.

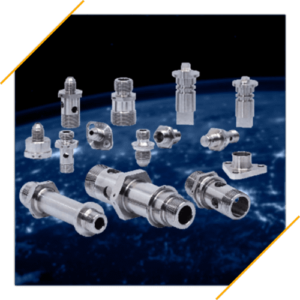

EXAMPLES OF PARTS FOR THE AEROSPACE SECTOR

- Aluminium air valve

- 316L stainless steel locknut

- Inconel flange fittings

- Titanium nipples

- EZ6NCT25 nozzles

- Super alloy nozzles

- Duplex nipple