HIGH PRESSURE

Your partner for function-critical parts that are crucial for the operation of your product

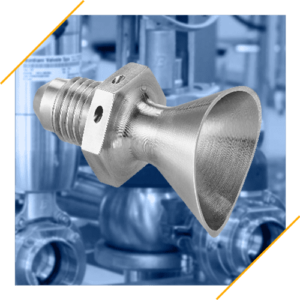

PARTS FOR HIGH PRESSURE SYSTEMS

The Tech critique process by Alpes Usinage guarantees the control and competitiveness of the machining process. The high technology and total traceability of all the stages of the process and of all the materials required allows us to control the risk and high definition of small and medium-sized production runs of bar turning

Pipe connection

Alpes Usinage’s design and engineering department takes into account the extreme thermodynamic conditions which mechanical connections might undergo when conveying liquids or gases under high pressure, sealing is achieved by direct contact between surfaces.

To ensure the conformity of the parts in contact, the sealing surfaces of the seats and the high-precision geometric gates are pre-lapped.

Currently, the parts are made of stainless steel, high-alloy steels or superalloys, on which a hard cobalt coating is applied, which has the following advantages :

- Low friction coefficient

- Good resistance to seizure and wear,

- Very high hardness for high contact and frictional stresses,even at high temperatures

- Very good mechanical characteristics and high resistance to corrosion in high-temperature water

- Good thermal shock resistance

EXAMPLES OF PARTS FOR THE HIGH PRESSURE INDUSTRY